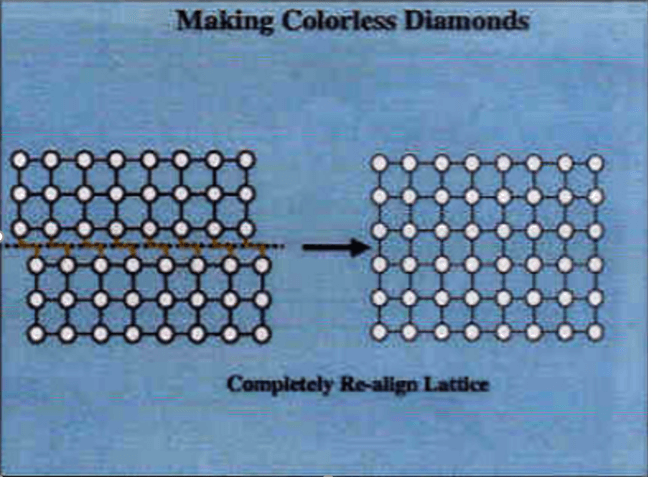

CVD diamond color enhancement also called HPHT treatment, HPHT annealing, is using high pressure high temperature method to improve CVD diamond color and clarity.

1) CVD diamond color enhancement theory: during CVD diamond growth, as lattice dislocation brown/coffee color core is occurred. To imitate natural diamond growth environment extremely pressure and temperature, certain high pressure and temperature are imposed on CVD diamond, which could make dislocation eliminated. At the same time, during CVD diamond growth, stress caused could also be removed. Then, colorless high clarity CVD diamond is achieved.

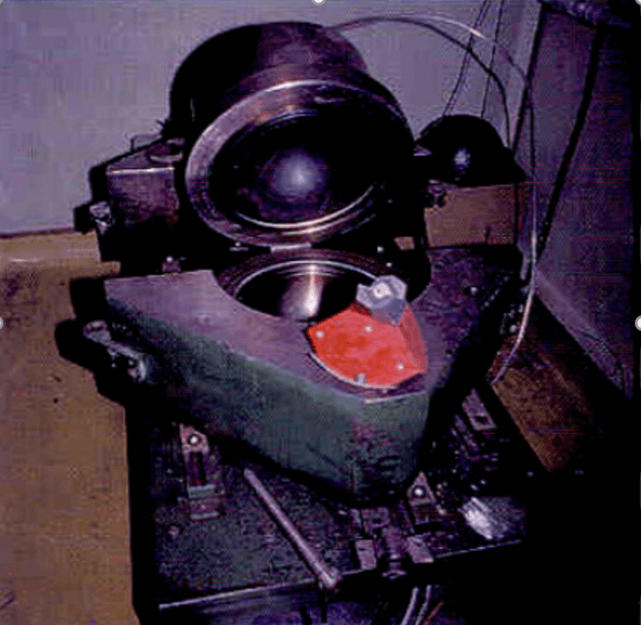

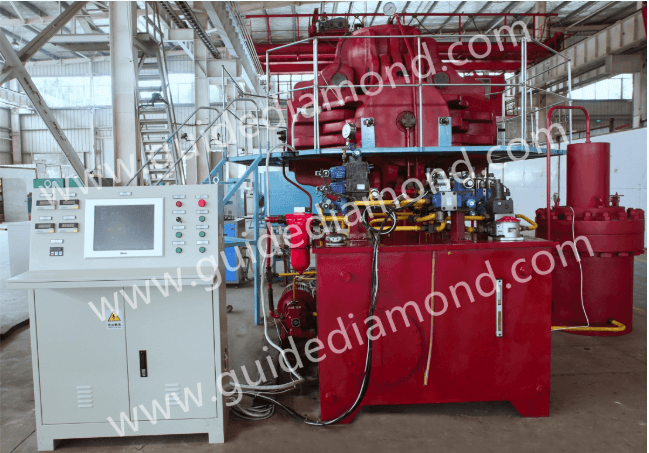

2) Equipment used to do CVD diamond color enhancement:

-1. Russian Bars:

-2. Chinese HPHT Cubic Press:

These are the two types which commonly are used worldwide. The advantage of Bars is occupying small area. But as inside cavity size is limit, only limit CVD diamond size could be treated. Whereas, with cubic press, polished diamond size treated is up to 7-8cts. With CVD diamond growing technology rapid improvement, CVD diamond size shall be larger and larger, which is the trend.

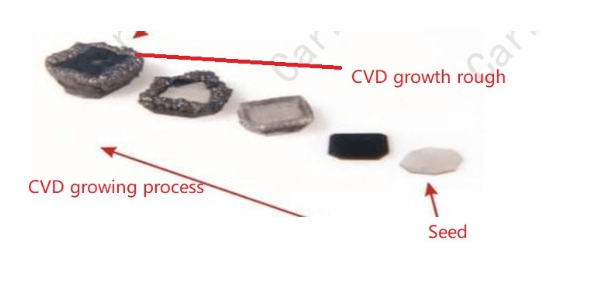

3) CVD diamond shape for HPHT treatment:

-1. Rough: CVD cube after removal polycrystalline;

-2. CVD half polished diamond;

-3. CVD polished diamond.

Before HPHT treatment, polycrystalline must be removed, otherwise which could lead to diamond broken.

4) After HPHT treatment, color permanent: as HPHT treatment, it is the method to imitate natural diamond growth. Thus, CVD diamond color after annealing is eternal.

5) Why choose us for CVD diamond color enhancement?

-1. Pyrophyllite container loading diamond is manufactured by ourselves. As we fully control raw material pyrophyllite container quality, it has made sure annealing process diamond enhancement stability and diamond completeness.

-2. Higher pressure and higher temperature: normally in the market, to do annealing, pressure and temperature used is 6.5GPa-7GPa with around 2000C. Whereas, we’re using higher pressure and temperature 7GPa-7.5GPa with around 2000C-2300C even more, which means color results could be better. Why market cannot do the same? Higher pressure with temperature means treatment equipment is closer to the extremest condition. It is like a car driving to the highest speed, which brings equipment under great risk. But we have unique equipment configuration and specification design for higher pressure and temperature. At the same time, raw material pyrophyllite container production is necessary to keep pressure transmitting stability, consistency and safety.

No comment yet, add your voice below!